The exhibition devoted to the production of traditional Christmas decorations

The production of blown Christmas tree ornaments has a long tradition. The tradition started in 1931 and still lasts. Thousands of ornaments of various shapes, sizes and decorations, which decorate trees around the world, has come to existence during this period.

The story of Christmas tree ornaments begins in a pattern room, where new patterns and colours are prepared for coming year. Own production of ornaments is carried out from summer to autumn. The production process has not been practically changed for all these years, all depends on skills of blowers and painters.

An exhibition introduces the tradition of ornaments production in the Dvůr Králové region. The first part is devoted to the production of glass beads and the production of Christmas tree ornaments itself. The production of beads is represented by the corner imitating a workshop, where beads are made. An installation creates an impression that we are in the bead maker´s workshop taking part in the production process. The remaining space is devoted to a production of blown Christmas tree ornaments itself. All production phases are represented here – blowing, dipping, decorating, clamping and packing into boxes.

Blowing

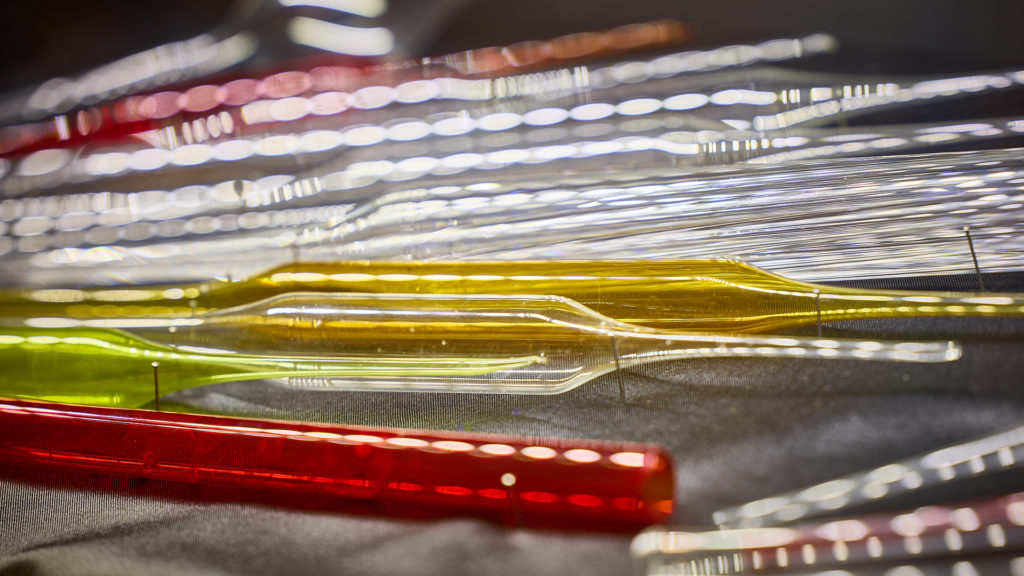

Hand blown glass ornaments are produced from rod glass with low fusibility temperature. It is processed thermally using flame. The basic shape for Christmas tree ornaments is a little tube (small body), from which the particular product is blown. It is prepared in a special pulling device from a glass tube. The tubes with a diameter of 16 – 40 mm are used for little tubes for all shapes, which differ only in size considering the final product. Glass is shaped by free blowing or blowing into a mold. The basic shape of free blowing is a ball. For one thing it is the final product, for another it is the basic shape for another processing over a burner for the creation of various shapes.

Another method of hand forming is blowing into a mold. The base is again semi-finished product “little tube“, which is after thorough warming inserted into ceramic mold. After closing a mold and blowing into the neck of the body the shape given by the mold is formed. All products blown into a mold are the same in terms of size and shape. Figures such as St. Nicholas, bears, dogs and the like are mostly blown. Products from a mold have a significant longitudinal weld.

Hand as well as machine shaped ornaments are passed on for another processing, which is surface treatment and decoration.

Silver-plating

An essential part of each collection are silver hand blown ornaments. The whole collection including basic shapes, molds, peaks, which have handling stems, could be silver-plated with reduction silver solution. The result is that the ornaments has the surface with metallic shine. Ornaments are filled with silver-plating solution using a dozer and afterwards soaked in a warm bath. Silver is deposited over the entire inner face of the ornament. Afterwards the product is necessary to rinse in clean water and dry.

Decorationods and each ornament is the original. Standard decoration method is called surface painting. In the past it was performed with boiled white zinc with an adhesive component for so called sprinkling. Colorful tempera paints with an adhesive component were also used. Silver and gold sprinkling were metal based so they became black after a certain period of time. Nowadays primarily latex and acrylic water-dilutable paints and imported artificial sprinkling in various colors are used. Especially modified colour glossy and matt paints are also used for decoration. Standard decoration is applied with brushes. Gentle decorations, so called written, are applied with glass pen “pisátko“.

In the last twenty five years the most frequent method used for surface decorations has been silk-screen printing. It is a printing method through a stencil on round and oval shapes. A graphic design is transferred in delicate netting by photographic process. Silk-screen printing decorations are used in complex figural ornaments, landscape and plant decorations. Silk-screen printing is used in one color and in basic drawing, colorization is made by hand. Printing is carried out with special silk-screen printing paints.

Another decoration technology is so called reflectors. Various decorations are impressed into pre-heated material with elements baked from a special ceramic material (so called buttons). Another method is gathering of glass, which is made with charcoal points.

Relief decorations is the secret product from the beginning of 1970s. They are line, leafy, very dense, but also gentle. They can be used with or without sprinkles. Another type of decoration is so called flocking. It is a technique, which uses a delicate velvet staple. The decoration is drafted with glue on an ornament, afterwards it is inserted into machine, where a velvet staple is with centripetal and electromagnetic forces glued onto applied paint. The result is velvet decoration. Christmas tree ornaments are further decorated using paper, textile and natural applications.

Clamping and packaging

In this phase the Christmas tree ornament is finished. Only a handling stem is cut off and a cap is inserted into an opening (gold or silver with an eye for hanging). In the end ornaments are packed into boxes and prepared for delivery to customers.

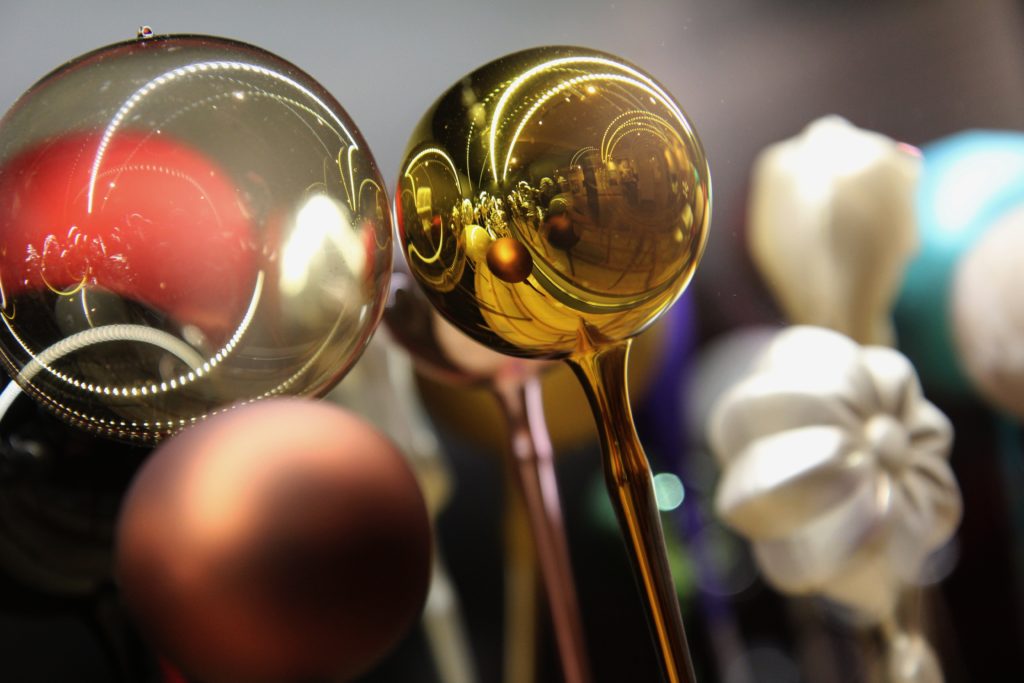

The other part of the exposition is a sort of “sample room“, where products produced in our region are presented. You can see a selection of Christmas tree ornaments from 1930s until present day forming a varied pallet of shapes and colours.